Electric heat pump water heater

Types of heat pump water heaters

Electric heat pump water heaters come in distinctively different configurations and system types. Although the technology involved is generally universal, the function of heat transfer, as well as tax credit eligibility, can vary depending on the system. With that said, which system type and configuration is more suitable will ultimately be determined by the particular application. Is Heat Pump Water Heating Right For You?

Before purchasing or installing an electric heat pump water heater, it's important to note that while the efficiency and the potential energy savings are attractive, heat pump water heaters are not viable or cost effective in every application.

Electric heat pump water heating is best suited in...

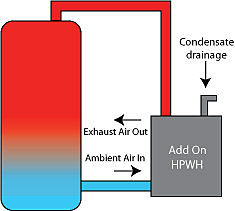

Add on heat pump water heaters  Add on electric heat pump water heaters are actually separate units designed to operate in conjunction with conventional water heating storage tanks. Add on electric heat pump water heaters are actually separate units designed to operate in conjunction with conventional water heating storage tanks.

Once retrofitted, an add on unit essentially converts a conventional storage tank into an electric heat pump water heater. In appropriate application, the add on heat pump unit is designed to supply all or most of the sites' annual hot water load.

Within the retrofit add on heat pump are all the components required for the air source refrigerant vapor compression cycle. Add on electric heat pump water heaters are relatively small, weighing anywhere from 30 pounds to 80 pounds, depending on the particular make and unit model. More times than not, add on units are designed for installation on electric storage tanks, although it's also worth noting that a select few add on HPWH can operate in conjunction with either electric or gas powered water heating storage tanks. Add on HPWH generally come equipped with electric temperature sensors as well as standard plumbing fittings. These standard fittings enable the heat pump to operate as the lower heating element of the conventional electric water heater. In such applications, the upper heating element is often designed to serve as the electric heat pump water heaters' back up power source. Add On HPWH and Heat Transfer In general, add on units utilize an external heat exchange, meaning the stored domestic water is heated outside of the insulated storage tank. Often times an internal pump is utilized to circulate the stored water to the condenser coil. Then the heated water is circulated and plumbed back to the insulated storage tank. Some add on electric heat pump water heaters utilize an internal heat exchange, meaning that the stored domestic water is heated within the insulated storage tank. These add on units come equipped with condenser coils that are designed for retrofit within the storage tank. An immersed condenser coil eliminates the need for an internal circulation pump. Add on units with immersed condenser coils (more times than not) are designed to operate with either electric or gas powered conventional storage tanks.

Add On HPWH Application Guidelines Depending on the particular model, an add on electric heat pump water heater can be installed away from the storage tank or mounted directly above the tank.

The electric requirements vary from model to model as well. Add on heat pump water heaters can operate on 230, 220, 208 or 110 volts. An add on HPWH that operates on 110 volts will generally offer additional flexibility in application, because these models are designed to plug into standard indoor electrical outlets.

An add on electric heat pump water heater that operates on 230, 220, or 208 volts will require an electrical outlet designed for a major appliance. An add on HPWH comes equipped with all the required plumbing and mechanical fittings, such as plumbing nipples, mounting brackets and a condensate drainage connection. Installation difficulty varies; ultimately it will depend on the particular model and application. There are additional considerations to make in order to determine if an add on electric heat pump water heater is best suited for your application; - Add on units are best suited in applications with existing conventional storage tanks. With that said, both the operating efficiency and the physical condition of the existing storage tank should be considered.

- The volume capacity of the existing storage tank is important as well. Manufacturers often specify adequate volume ranges that will support proper and efficient heat pump function. Failure to consider the existing storage tanks' volume can result in a reduction of efficiency and/or an inadequate first hour rating.

- The designed mount should be considered as well. In applications with mounts, a specified amount of topical clearance is generally required in order to ensure proper function of the add on electric heat pump water heater. In applications with gas powered storage tanks, an adequate amount of clearance will be required for the tanks' gas flue as well.

Add On HPWH and Water Heater Tax Credits Although several manufacturers have formally requested inclusion into the DOE Energy Star Program, add on electric heat pump water heaters currently are not energy star certified. Efficiency and performance aside; the U.S Department of Energy has concluded that all units designed for retrofit shall be omitted from the energy star program. With that said some add on units do exceed the Energy Star Programs' efficiency and performance criteria. Units that meet efficiency and performance criteria are eligible for the federal water heater tax credit as well as several state wide tax credits and rebate programs.

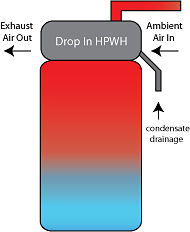

Drop in (hybrid) heat pump water heaters  Drop in electric heat pump water heaters are often referred to as hybrid or integral units. Drop in units incorporate both the air source heat pump and the storage into one integrated standalone system. Drop in electric heat pump water heaters are often referred to as hybrid or integral units. Drop in units incorporate both the air source heat pump and the storage into one integrated standalone system.

If properly sized, a drop in HPWH (along with the integrated back up electric heating elements) can supply the sites' entire annual hot water load. An integrated drop in or hybrid unit can serve as an energy efficient electric powered back up system for a solar hot water heater as well. Overall the hybrid electric heat pump water heater is a new development in both residential and light commercial water heating. This industry development was made possible in large part by the ORNL (The Oak Ridge National Laboratory) along with the sponsorship of the U.S Dept. of Energy. With these developments, several large appliance manufacturers have developed hybrid electric heat pump water heaters and other manufacturers have introduced plans to introduce residential drop in units as well. Hybrid units, similarly to add on units, come equipped with electric temperature sensors as well, except such fitting are internal. So with these standalone units, retrofitting is not required during the installation process. Drop in heat pump water heaters come equipped with two conventional electric heating elements, designed to serve as the heat pumps' back up power source. Drop In (Hybrid) HPWH and Heat Transfer Depending on the particular make and model, a drop in electric heat pump water heater can utilize either an external or an internal heat exchange. Some drop in units are equipped with internal water circulation pumps designed to redirect the stored domestic water to the condenser coil. These water pumps also recirculate the then heated water back to the insulated storage tank. In these units, an external heat exchange occurs, meaning the stored domestic water is heated outside of the insulated storage tank. Other drop in units are designed with an immersed condenser coil. Drop in units with immersed condenser coils don't contain water circulation pumps. In these hybrid units, an internal heat exchange takes place, meaning the stored domestic water is heated within the insulated storage tank.

Drop In (Hybrid) HPWH Application Guidelines Drop in, hybrid and integral electric heat pump water heaters are designed with standard plumbing fittings as well as standard electrical requirements, operating on 230, 220 or 208 volts. In fact with the exception of a condensate drainage connection, a hybrid unit has an identical footprint as an electric powered conventional storage tank. It's important to note that a hybrid electric heat pump water heater, more times than not, is larger (in length) and weighs more than a conventional storage tank with an equal volume capacity. The greater length (and possibly the weight) may require some consideration in applications in existing homes. There are additional considerations to make when determining if a hybrid electric heat pump water heater is best suited for a particular application; - Drop in units are best suited in applications that either require or desire water heater replacement. This is especially the case in applications that require replacement of an electric powered storage tank.

- Drop in units are suitable for new constructions, especially sites designed to use electric powered major appliances and those without access to natural gas. In some applications electric heat pump water heaters can be more efficient and cost effective than gas powered storage tank systems.

- It's important to note, that in new constructions the electric footprint of the system must be accounted for during the design and building process.

Drop In HPWH and Water Heater Tax Credits Due to the standalone design of these units, drop in or hybrid electric heat pump water heaters are eligible for inclusion in the U.S DOE Energy Star Program. The overwhelming majority of drop in units, especially those introduced by large appliance manufacturers, do exceed the Energy Star Programs' performance and efficiency criteria, making these models eligible for the federal water heater tax credit as well as several other state wide tax credits and rebate programs.

Integrated and full demand systems Air source and ground source (or geothermal) heat pumps associated with central space cooling and space heating systems incorporate a similar refrigerant vapor compression cycle as both add on and drop in electric heat pump water heaters. With that said, central heat pump (both air source and geothermal) space cooling and space heating systems can be retrofitted and pre designed to perform the additional function of water heating, creating an integrated heat pump system. In fact manufacturers of geothermal space cooling and heating systems often offer domestic water heating as an optional auxiliary feature. Industry professionals often refer to these integrated designs as full demand systems. Integrated and full demand systems, if applied correctly, can provide a significant amount of the annual hot water load. With that said, in these designs a back up power source will be required as well.

Desuperheaters Desuperheaters are refrigerant to water heat exchangers that are designed and retrofitted on air source and ground source heat pump systems for heat recovery. Desuperheaters harness the excess heat (often referred to as super heat) of the systems' compressor, and transfer the super heat to stored domestic water. It's the addition of a desuperheater, and the super heat recovery it provides, that enables an air source or a geothermal space cooling and space heating system to perform the additional function of electric heat pump water heating. Air source and geothermal heat pumps are otherwise designed to expel the super heat produced by the compressor into the surrounding air or into the ground. With the addition of a desuperheater this wasted heat can be efficiently utilized.

Application guidelines

The benefits of a desuperheater and utilizing an air source or ground source heat pumps' excess heat for electric heat pump water heating is worth considering, this is especially the case for new constructions. With that said, the regional climate of the site, the actual or estimated heat pump run times, as well as the existing or potential flexibility of storage volume capacity must be considered when determining application.

Regional Climate; Annual Space Cooling and Space Heating Loads

Regional climate is important when determining application because in integrated and full demand systems, the overall water heating efficiency will vary depending on the systems' central space conditioning loads.

Space Cooling and Desuperheater Operation

During the space cooling mode, the air or ground source vapor compression cycle is designed to extract heat from conditioned spaces, and exhaust heat outdoors into the surrounding air or ground. In essence, it's this same excess heat that's harnessed by the desuperheater to heat domestic water. So the heat recovery produces a cost free heat pump water heating source. It's also important to note that operating a desuperheater during the space cooling season can actually increase the overall efficiency of the heat pump, by reducing both the load on the systems' compressor and the condenser.

Space Heating and Desuperheater Operation During the space heating mode, the central systems' vapor compression cycle is reversed and designed to harness heat from either the surrounding outdoor air or from the ground, and then exhaust this heat indoors. It's important to note that operating a desuperheater during the space heating season translates into the harnessing of heat that would otherwise be used for the space heating load. In essence, electric heat pump water heating would reduce the systems' overall BTU output, and depending on the particular application and load, this reduction in output can reduce the overall efficiency of the central space heating system.

Annual Desuperheater Operation Annually operating a desuperheater can be efficient, especially in applications in mild to warm climate regions, and in applications with less efficient back up water heating systems. In some applications, deactivating the auxiliary electric heat pump water heating option during the space heating season and allowing the back up to resume the hot water load may be advantageous. With that said, it's important to note that in many climate regions both the space cooling and heating load can significantly to moderately decrease during the fall and spring. This is noteworthy because with integrated and full demand systems, electric heat pump water heating is viable only when the heat pump of the space cooling and heating system is operating.

Heat Pump Run Time and BTU Output

Since the heat pump of the central space cooling and heating system is designed to provide the hot water load, the systems' heat pump run time, or the duration of operation, is important to consider when determining application.

The heat pump run time is largely determined by the total square footage of the conditioned spaces and the systems' output, which is measured in BTU or British Thermal Units.

The BTU output is largely determined by the particular model as well as the size of the system. It's important to note that in some applications (especially with air source heat pumps) the outdoor climate temperature can significantly impact the systems' BTU output as well.

Sites with large conditioned spaces more times than not have large systems that produce greater thermal outputs. It's also important to note that in existing sites with undersized systems, longer heat pump run times are often required in order to compensate for the undersized central system. When retrofitting a desuperheater on an existing system, such factors should be considered.

Storage Volume Capacity

When determining application, the storage volume capacity should be considered as well. Since the systems' heat pump run time and the sites' hot water demand schedule cannot be coordinated, a large storage volume is generally required in order to fully maximize on the heat recovery provided by the desuperheater.

This is especially the case in applications with either long heat pump run times or large outputs. An insufficient storage volume compromises the systems' efficiency by limiting the amount of domestic water available for the daily heat recovery.

Most industry professionals agree that a storage capacity greater than the total daily hot water use is required in order to fully benefit from the desuperheaters' daily heat recovery.

Single Tank vs. Preheat or Buffer Tanks

Integrated as well as full demand geothermal systems can be designed with one or two tanks. In a single tank system, the desuperheater is plumbed directly to the insulated storage tank.

Often times an electric powered tank is utilized, and the temperature setting on the lower heating element is either lowered or deactivated altogether. Industry professionals and manufacturers often recommend lowering or deactivating the heating element in order to maximize on the heat pump run time and the output.

In a two tank system, a preheat or buffer tank is plumbed to the desuperheater, and the preheat tank is plumbed to either another tank or back up source.

Depending on the desired level of efficiency, the preheat tank can be plumbed to a retrofitted add on HPWH, a drop in or hybrid electric heat pump water heater, a solar hot water tank, or a thermostatic tankless hot water heater.

Preheat or buffer tanks are commonly used to more effectively leverage the heat pump run times and the BTU outputs. Industry professionals and manufacturers often recommend using a preheat tank when installing a full demand system, or when retrofitting a desuperheater to an existing system.

More on electric heat pump water heaters More on energy efficient water heating Other energy efficient water heating options

|